CALTECH ENGINEERING SERVICES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CALTECH ENGINEERING SERVICES

Cathodic Disbondment Test Equipment

Caltech Engineering Services India is a leading manufacturer for multi-channel potentiostat / cathodic disbondment tester / cathodic disbondment test equipment for testing the resistance to cathodic disbonding. Cathodic disbonding tester is designed to test and accurately determine the characteristics of insulating coating systems applied over steel material. Cathodic disbondment test equipment has high accuracy in potential (measured and applied), limits of deviations between the actual and reported

Corrosion Coupons

Caltech Engineering Services manufacture, supply Strip / Rectangular / Disc / Welded Coupons, Stressed Coupons and other range of corrosion coupons test that accurately determine the corrosion of metals in various service conditions. Strip type corrosion coupons are produced in number of sizes, shapes, and material as per customer needs. Corrosion coupons meet NACE Standard requirements and tested before shipment.

While ordering test coupons, please refer technical specifications, type of material you are testing, size of coupons, surface finish, mounting holes and locations.

Corrosion coupons are supplied in VCI Bags for excellent storage of ferrous and non- ferrous coupons. VCI bags supplied generally protect material up to 1 year under proper environment conditions.

Rapid Chloride Permeability Test Equipment

Caltech Engineering Services offers Rapid Chloride Permeability Test Apparatus. Rapid Chloride Permeability Test Equipment (RCPT) has multi-port testing facilities is designed to test concrete samples of 100mm diameter with 50mm thickness for concrete ion permeability test. All the easy connections are ready to use chloride ion permeability test instrument.

Customer can test up to four samples at a time as per ASTM C1202 - Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration, AASHTO T277- Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration (Rapid Chloride Permeability Test) and ASTM C1760 - Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete

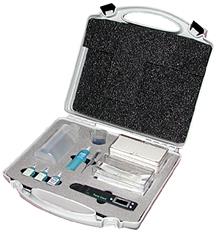

Rebar Corrosion Voltmeter

Caltech Engineering Services offer DV-05 rebar corrosion voltmeter kit complete economical kit for identifying areas of rebar corrosion in concrete as per ASTM C876. This standard describes procedure for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete

DV-05 rebar corrosion voltmeter kit includes half cell and voltmeter integrated with a high impedance and long earth cable and despensing damp sponge. When rebar corrosion voltmeter DV-05 is connected between the reinforcing steel, Cu-CuSO4 reference half cell electrode (Fontana-101F) and specially made highly electrical conductive despensing sponge on the concrete surface where a measurement can be made for the half-cell potential. This gives measurement of the probability of corrosion activity. By testing at a fixed distance apart, a grid of half-cell potentials can be developed and areas delineated. This test method covers the estimation of the electrical half-cell potential of uncoated reinforcing steel in field and laboratory concrete, for the purpose of determining the corrosion activity of the reinforcing steel

S.S.C Proof Rings

Caltech Engineering Services India manufacture and supply proof ring to test and accurately determine the resistance to sulfide stress corrosion cracking (SSC) and stress corrosion cracking of metals in H2S environment or service. Proof rings and associated accessories are manufactured to meet requirements of NACE TM0177 and material standard requirements as per MR 0175.

Leading laboratories with best H2S testing capabilities uses Caltech Engineering Services India supplied instruments. Complete range of corrosion testing instruments assists to prevent corrosion and control corrosion in oil & gas, sour gas production, offshore, gas treating plants, and petroleum refineries.

Bent Beam Test

Caltech Engineering Services India manufacture and supply stress corrosion cracking bent-beam testing instument to accurately determine the resistance to sulfide stress corrosion cracking (SSC) as per NACE TM0177 Standard Method B and ISO 7539. We also supply defection device for measuring accurately deflection achieved by bending. NACE TM0177 describes Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments

NACE TM 0177 Method B, the NACE Standard Bent-Beam Test, provides for testing carbon and low-alloy steels subjected to tensile stress to evaluate resistance to cracking failure in low-pH aqueous environments containing H2S. The compact size of the bent- beam test specimen facilitates testing small, localized areas and thin materials. Bent beam test specimens loaded to a particular deflection give a failure/no-failure test result. We recommend to use this test for thin material thickness or low diameter pipe materials and welding test. This method involves deflecting each test specimen in a series by applying a bending stress. The stressed test specimens then are exposed to the test environment, and the failure (or no-failure) by cracking is determined hence becoming very popular and easy test method for labs. There is also benifit in the method which constitutes a constant- deflection test of low test specimen compliance. The computed stress is called a pseudo-stress because it does not reflect. At a time 12 to 16 samples can be tested.

Four Point Bend S.S.C Test

Caltech Engineering Services manufacture and supply four point bending SSC test jigs, and also test vessels to test and accurately determine the stress corrosion cracking susceptibility of metals in H2S service. Test rigs meet requirements of ASTM / NACE Standard TM-0177 and suitable to test material as per requirements of NACE MR0175. Main objective of this test is to evaluate materials for the service behavior or to screen alloys for service in a specific severe environment for an accelerated time. The 4-point bend SSC test is performed using ASTM G-39 and NACE TM0177 standards.

Hydrogen Induced Cracking Test

Caltech Engineering Services manufactures hydrogen induced cracking testing apparatus ( HIC test ) to test and accurately determine the hydrogen induced cracking over exposed test specimens as per NACE standards requirements. HIC testing is recommended to evaluate the resistance of pipeline and pressure vessel plate steels to hydrogen induced cracking corrosion caused by hydrogen absorption from aqueous sulfide corrosion. Unstressed test specimens are exposed to a solution at temperature of 25deg cent with continuous H2S gas flow. The test specimens are finally removed and evaluated. Test specimens determine susceptibility of metals in H2S service. HIC testing apparatus meet requirements of ASTM / NACE Standard TM0284 and suitable to test material as per requirements of NACE MR0175.

S.S.C Temperature Pressure Vessels

Caltech Engineering Services is pleased to introduce latest designed, user friendly, economical High Temperature Pressure Vessels combines with SSC proof rings manufactured to test and accurately determine the sulfide stress cracking susceptibility of metals in H2S service.

SSC Proof Ring is provided with ready conversion chart that can accurately determine specimen load. It also provides sustained specimen load under a stress state of uniaxial tension. SSC Proof Rings are supplied with dial Indicator providing a check for deflection.

Salt Spray Test Apparatus

Caltech Engineering Services manufactures salt spray testing instrument. Salt spray test is also called as Fog Test. This is an accelerated environmental corrosion test in which metal specimens are exposed either continuously or intermittently to a fine mist of salt-water solution used to evaluate the resistance to corrosion of paints, coatings, or electrical connections. The appearance of corrosion products (oxides) is evaluated after a period of time. Test duration depends of the corrosion resistance of the coating; the more corrosion resistant the coating is, the longer the period in testing without showing signs of corrosion.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.